| |

Our company provides 1000 tons to 10000 tons

of Teflon seals and guide rings for China's large forging

machinery, accounting for 85% of the market share. Keep a

record of zero leakage for more than 10 years!

A.Performance and purpose

It can be divided into hole and shaft. It is composed of an

anti-wear filled PTFE ring and an O-ring. The O-ring provides

preload, which can compensate for the wear of PTFE square

ring. The friction coefficient of PTFE is small and the dynamic

and static friction coefficients are similar. It is suitable

for high and low speed reciprocating motion and high pressure

system, with two-way sealing effect. It is generally used

together with guide ring. For specifications with hole diameter

less than Φ 40, split groove shall be adopted.

B.The material of wear-resistant ring is polytetrafluoroethylene

PTFE, and the O-ring is NBR or FKM.

C. Working conditions

Reciprocating speed: ≤ 5m / S

Working pressure: 0 ~ 40MPa

Service temperature: - 40 ℃ ~ + 260 ℃ (depending on the material

of O-ring) Working medium: hydraulic oil, gas and water

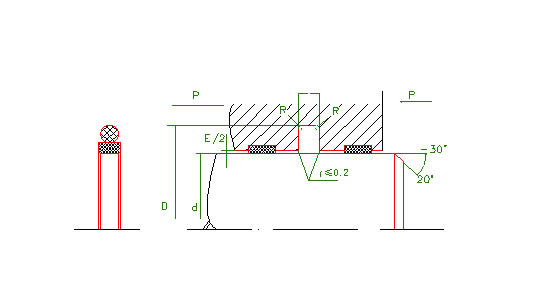

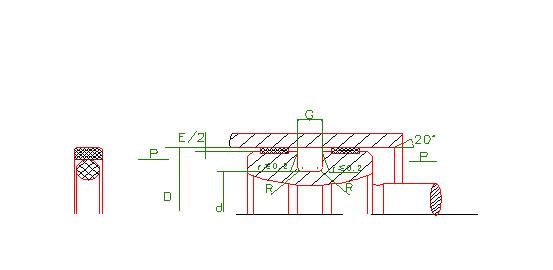

D. Structural device

|

|